Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

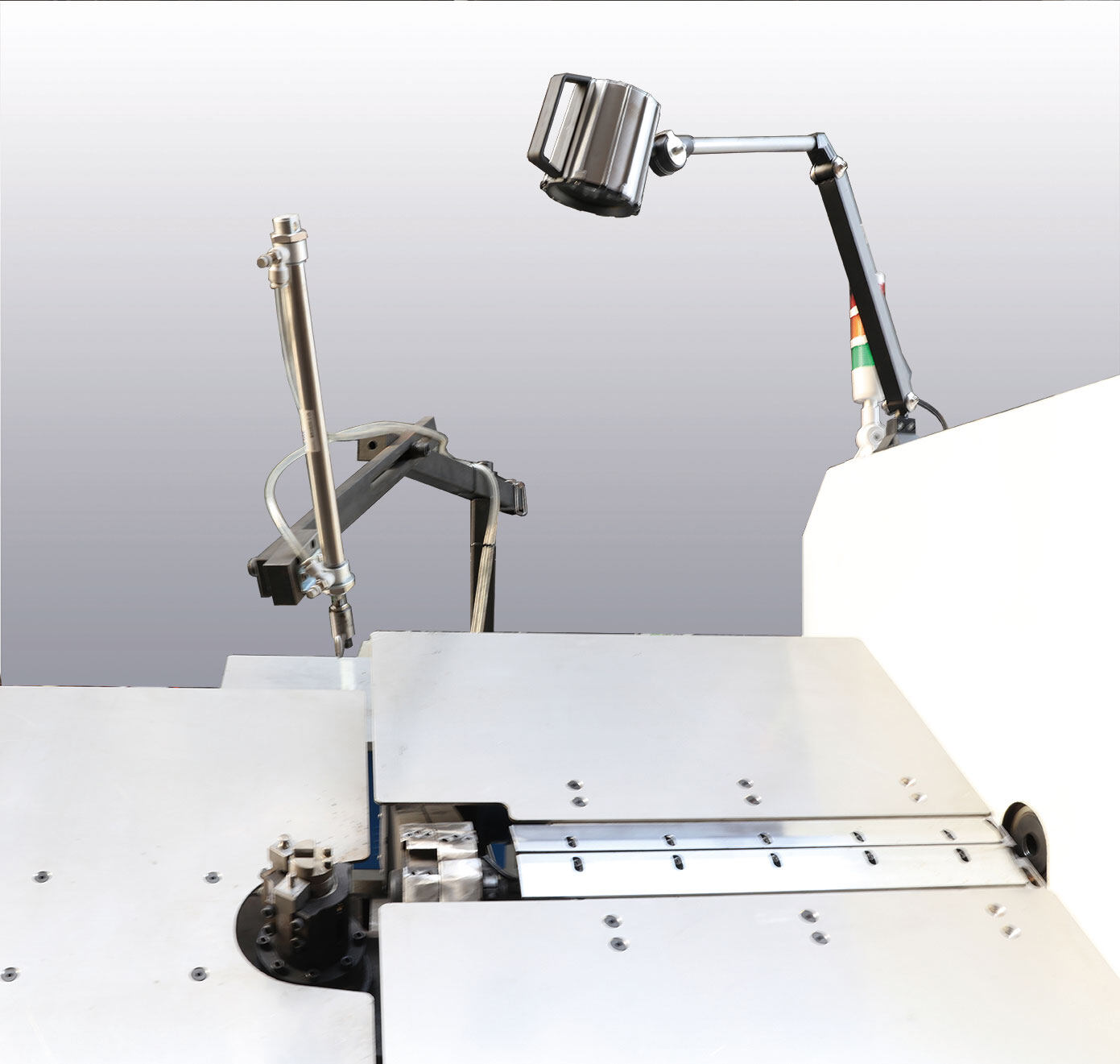

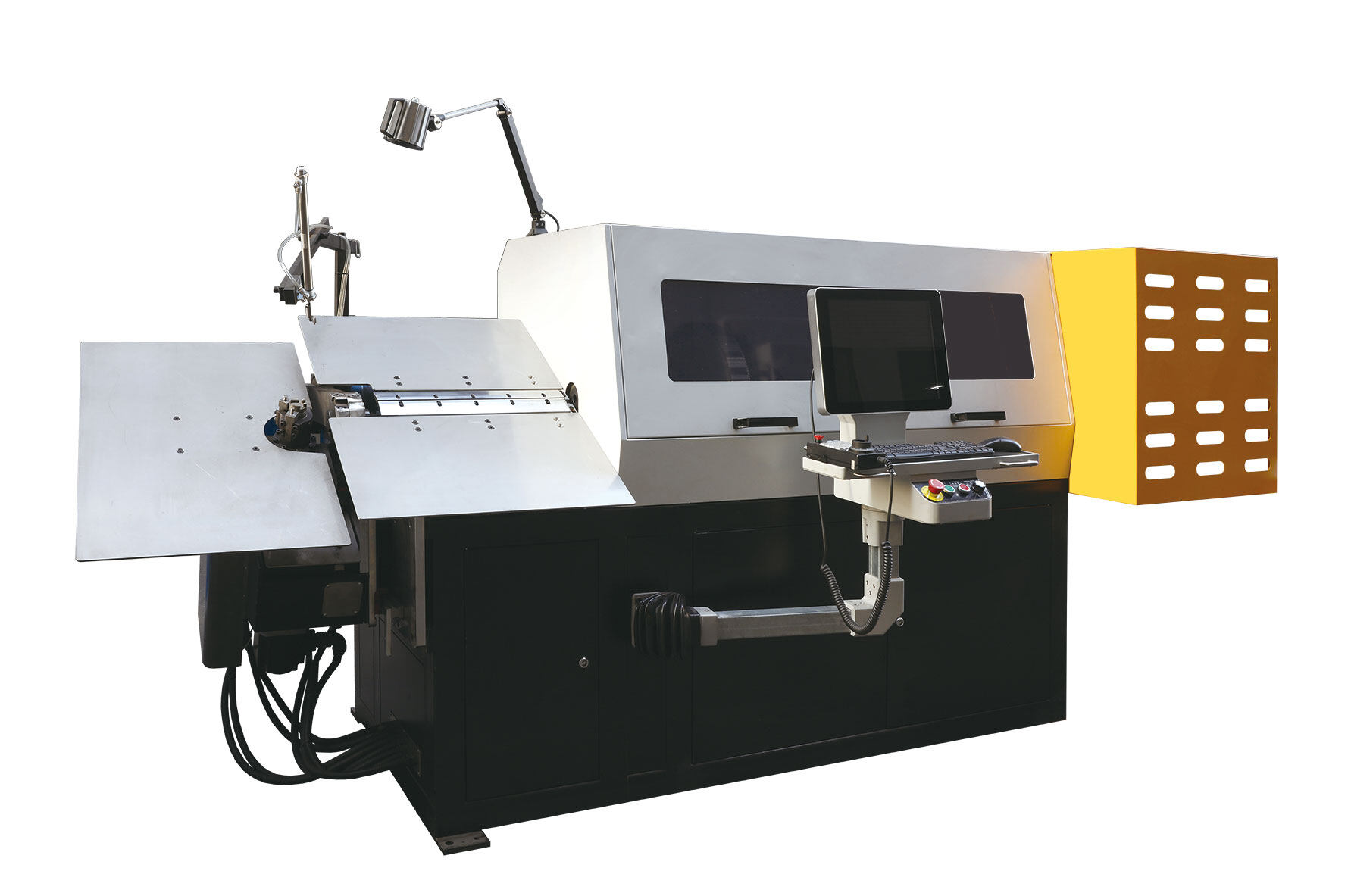

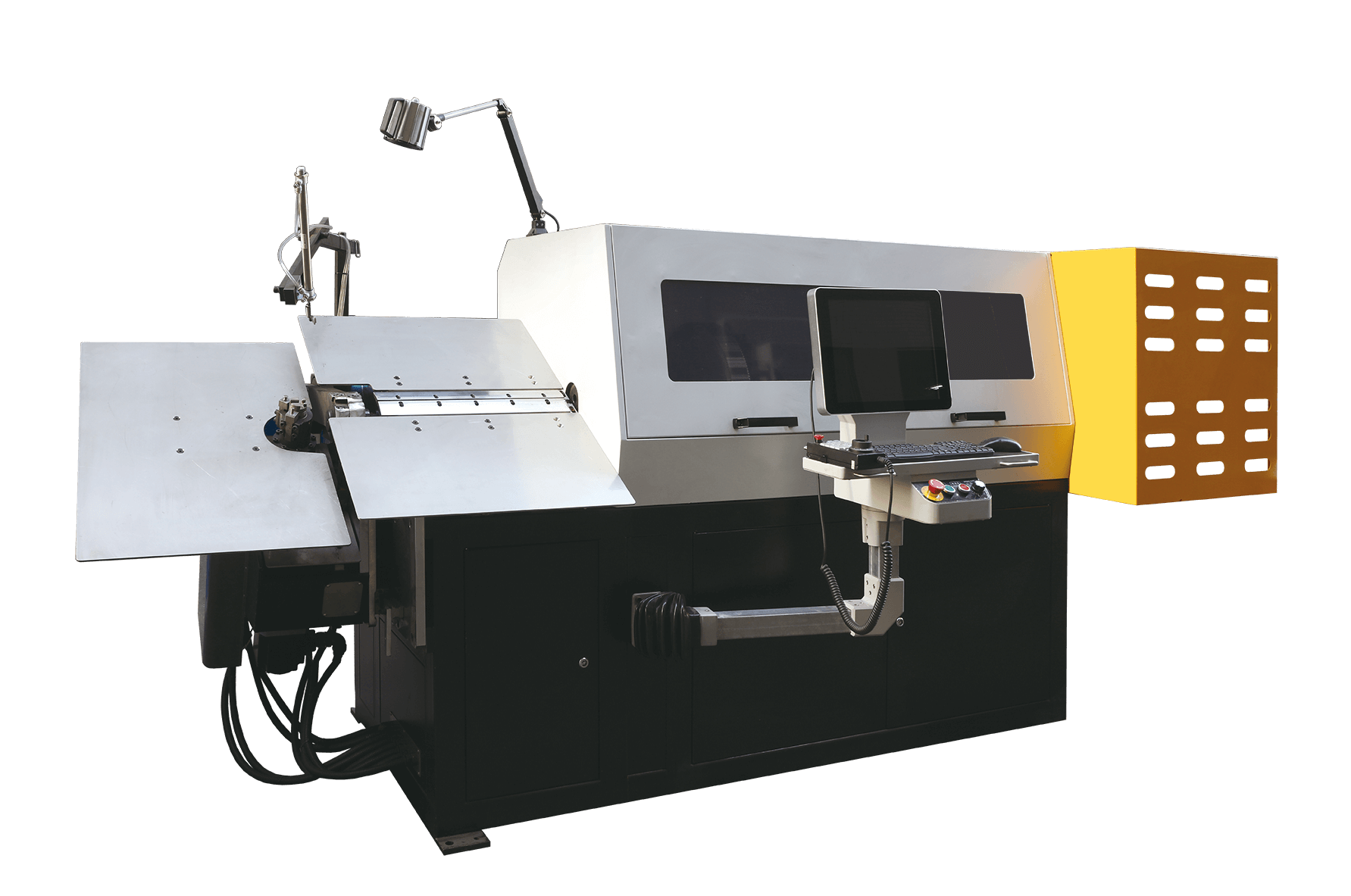

Wire-Rotating 3D Wire Bending Machine

The wire bending machine is equipped with a professional servo motor, which drives the wire feeding wheel to rotate and controls each step of forming by the computer system.

Product selling points

The wire-rotating 3D wire bending machine is applied to the automobile parts industry, including the forming of automobile seat steel wire and automobile seat accessories; Pet cage accessories; Kitchen hardware accessories; Garden tool accessories; Electronic product molding; Toy accessories molding; Electrical accessories molding; Sports equipment accessories molding; Stationery accessories molding; Instrument accessories molding; Instrument accessories molding; Hair accessories molding; Kitchen and bathroom accessories molding; Handicrafts molding; Supermarket shelf accessories molding and other high-precision metal wire forming accessories fields.

- The precision servo motor drives the wire feeding wheel to rotate, and the professional wire bending machine computer system controls each driver to perform each step of forming. The servo motor's slow rise and slow fall curve and the servo motor speed can be modified arbitrarily according to the need, to eliminate the impact of mechanical transmission and ensure that the actual length of the iron wire is consistent with the theoretical calculation length;

- In the design budget, the length of each MM has been divided into 10 pulses, which further ensures the setting of length accuracy and the wire feeding accuracy can be controlled at 300 ± 10 wires;

- The adjustable servo shear can ensure the uniformity of the circle cut, and the cutting time and the withdrawal time can be directly modified on the text display;

- It is designed with manual slow feeding and slow returning functions, which are easy to operate and reduces material loss.

Machine features

- The unique transfer line structure design is light and fast to ensure rapid and stable production operation.

- The computer starts and shuts down quickly, and the operation is simple and convenient. The computer interface can change the program while adjusting speed during production.

- Equipped with Japanese high-speed motor, Taiwan reducer, high production speed.

- The production can realize no change in the angle at the slowest angle folding, and the production stability is better. The wire feeding and the rotating arm are separated and matched. When the wire is rotated, the wire is not rotated, and the small outer diameter arc and multi-circle product can be formed.

- Imported bearings and other important parts are durable and reliable. The production can realize the angle at the slowest angle, and the production stability is better.

- High precision wire feeding box, bearings, gears, and other important parts are imported from Taiwan to ensure that the wiring error is reduced to plus or minus 0.1mm, and can be used as wire forming products within the range of 2.0-14 mm wire diameter. The quality assurance is 8760 hours, and the equipment is durable and reliable.

- The control system can be connected to the Internet and connected to WiFi via mobile phone or computer to realize remote control, which is convenient and fast after sales.

- The supporting use of the steel wire butt joint machine makes the line-changing operation of the machine more convenient.

Foshan Jinchun Industrial Automation Technology Co., Ltd. was established in 1998. It is a technology-intensive industrial company specializing in the development of welding technology and equipment research and manufacturing, integrating scientific research, production, and sales.

With rich experience and strong technical personnel, the company constantly innovates and develops various types of high-quality hardware wire rods, hardware mesh baskets, and other mechanical equipment. It has formed five series of electric fan and industrial fan guard production lines, wire tube evaporator and condenser production lines, pet cage production line, bag cage frame production line for bag filter, buckle machine, and chain machine production line. The company has accumulated more than ten years of development, production, and operation of welding machines and related products. The products are widely used in the fields of manufacturing and production of hardware appliances, lighting, kitchenware shelves, decorative handicrafts, cultural and sports products, electrical and electronic communication batteries, and industrial equipment automation. With a very wide user group.

The company pursues management to promote efficiency, quality for survival, technology for development, strictly implement the national quality assurance system standards, provide customers with high-quality, stable, and reliable products, and perfect high-quality services. Welcome people from all over the world to visit the company. business, and work together to create a better tomorrow.